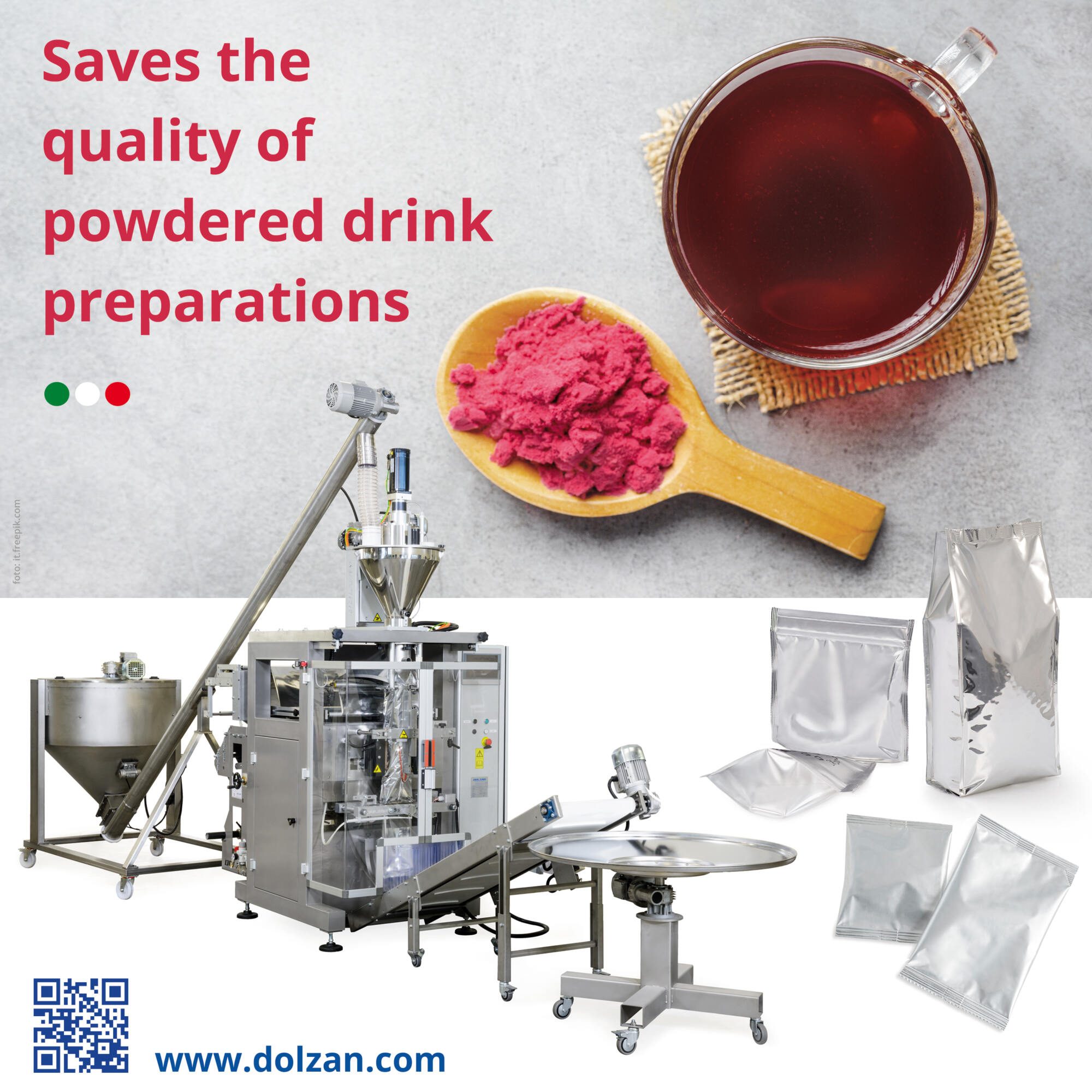

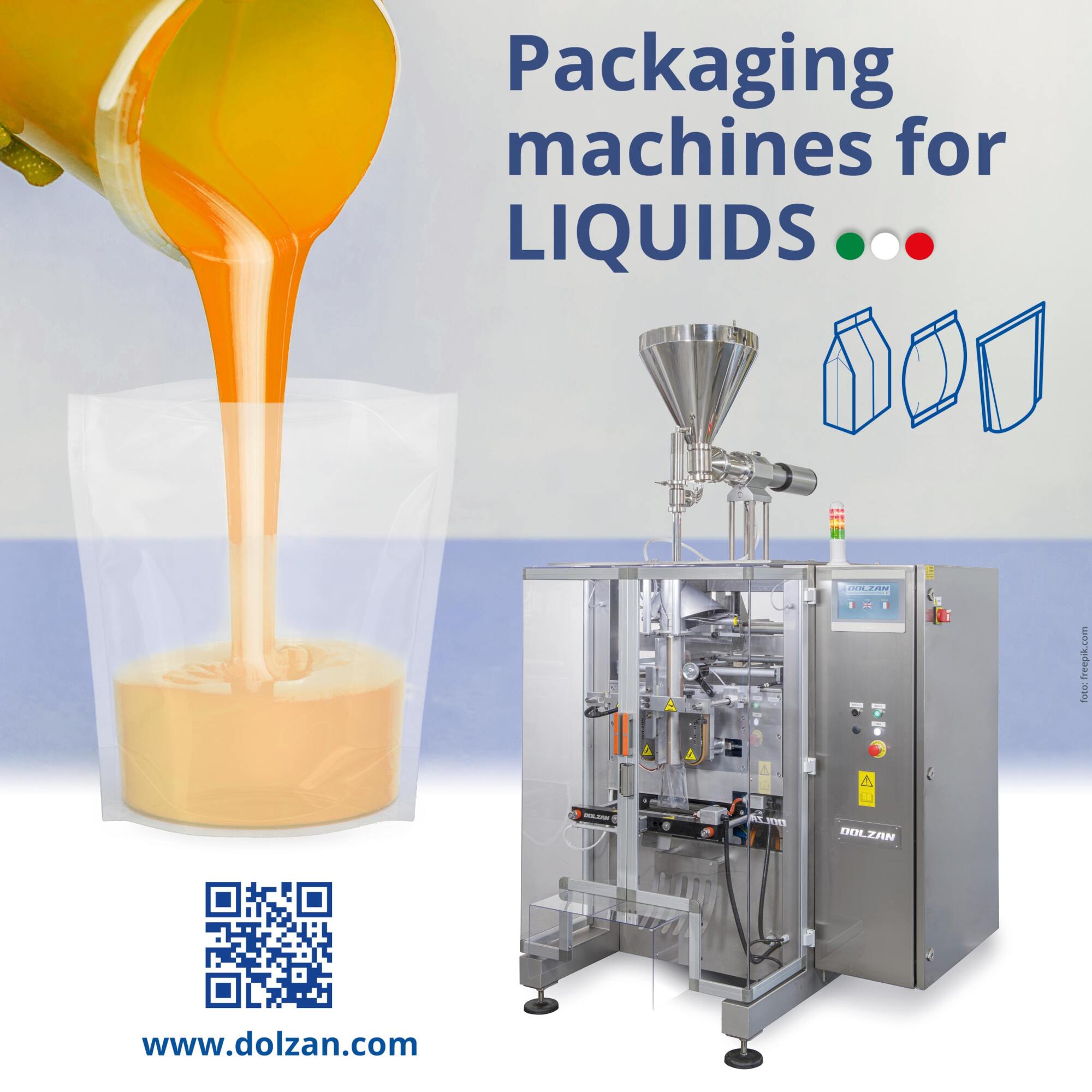

Packaging Machines for Liquids, Creams & Hot Products

Packaging Machines for Liquids, Creams, and Hot Products

Packaging liquids in pouches is increasingly popular in the food, cosmetic, chemical, and pharmaceutical industries. Dolzan’s vertical packaging machines provide effective, tailor-made solutions for all dosing needs—from light liquids to thick, creamy, or hot products, including those with solid pieces.

With over 50 years of experience, Dolzan designs fully customizable machines aimed at maximizing efficiency, reducing costs, and meeting the highest hygiene and environmental standards.

🔗 Discover the full range: https://www.dolzan.com/en/portfolio-item/liquidi/

Packaging machine for milk in bag.

Advantages of Liquid Pouch Packaging

Choosing to package liquids in flexible pouches offers numerous significant benefits:

- Cost efficiency: Flexible pouches reduce packaging material costs compared to traditional rigid containers like bottles or jars, leading to savings in both materials and shipping expenses due to lower weight and volume.

- Space optimization: Pouches occupy less space in storage and during transportation, allowing businesses to improve logistics efficiency and reduce carbon footprint.

- Consumer convenience: Flexible pouches are easy to handle, store, and open, often featuring resealable options such as zip locks or spouts, making product use more convenient.

- Versatility in packaging formats: Dolzan machines can package liquids into a variety of pouch types and sizes, including pillow bags, doypacks, and gusseted pouches.

- Sustainability: Our packaging systems are compatible with recyclable, compostable, and mono-material films, enabling brands to meet growing consumer demand for eco-friendly packaging solutions.

Handling a Wide Range of Products: From Thin Liquids to Thick and Hot Substances

Dolzan’s advanced dosing technology allows packaging of liquids across a wide viscosity range, as well as products with particulate matter or those requiring temperature control during filling:

- Thin, fluid liquids: Water, fruit juices, oils, and beverages are efficiently dosed and sealed without leakage or contamination.

- Thick and viscous products: Creams, sauces, honey, nut butters, and spreads are handled with precision, maintaining product integrity and texture.

- Products with pieces: Soups, stews, and sauces containing vegetables, meat chunks, or other solids can be accurately portioned and packaged without damaging the product.

- Hot filling: Certain applications require filling at elevated temperatures (e.g., hot soups or sauces). Dolzan machines are engineered to maintain food safety standards and product quality during hot filling.

Specialized Packaging for Creams, Sauces, and Viscous Products

Dolzan’s packaging machines are designed to meet the unique challenges of filling viscous and creamy products:

- Sweet creams: Nut spreads, dessert creams, jams, and other sweet viscous products can be packaged with gentle handling to avoid product degradation.

- Savory creams and sauces: Spreadable cheeses, pâtés, mayonnaise, ketchup, and other savory sauces are filled with precise dosing to ensure consistent weight and presentation.

- Soups and ready meals: Hot or cold soups, broths, and ready-to-eat liquid meals with pieces benefit from packaging solutions that maintain quality and prevent contamination.

The machines’ modular dosing systems and flexible pouch configurations allow for customized solutions based on product characteristics and production requirements.

Commitment to Sustainable Packaging

At Dolzan, sustainability is a core value. Our packaging machinery supports the use of eco-friendly materials to reduce environmental impact. This includes compatibility with:

- Recyclable films: Facilitating circular economy initiatives by enabling pouches to be recycled more easily.

- Compostable films: Offering solutions for fully biodegradable packaging, meeting consumer demand for green alternatives.

- Mono-material films: Simplifying recycling processes compared to multilayer laminates.

By integrating these materials into your packaging lines, your brand can enhance its environmental responsibility and align with evolving regulatory standards.

Ensuring Food Safety: MOCA Compliance

Dolzan guarantees that all materials in contact with food products comply with MOCA (Materials and Objects in Contact with Food) regulations, a crucial aspect for food industry clients. This ensures:

- Maximum hygiene throughout the packaging process.

- Full traceability of all materials used.

- Safe contact with food products, including those that are hot or sensitive.

Our quality management systems adhere to international standards to ensure that your packaged products meet all regulatory and safety requirements.

Wide Range of Packaged Products

🥗 Food – Liquid and Semi-solid Products

- Sauces and dressings

- Sweet and savory creams

- Soups, broths, veloutés

- Juices and beverages

- Vegetable oils

- Liquid dairy products

- Fruit pulps and sauces

- Ready liquid meals

🧴 Non-Food – Cosmetics, Chemicals, and Technical Products

- Shampoos, lotions, detergents

- Lubricants and technical oils

- Paints, glues, inks

- Fertilizers and pesticides

- Syrups and pharmaceutical solutions

Tailor-Made Solutions for Every Production Line

Every Dolzan system is configurable for:

- Pillow, doypack, zippered, or easy-open pouches

- High-output automatic lines

- Quick format changeovers

- Easy cleaning and maintenance

- Intuitive interface for production management

Contact Us for Your Liquid Packaging Project

Dolzan Impianti is your ideal partner for reliability, flexibility, and innovation in packaging liquids, creams, and complex products.

🔗 Learn more: https://www.dolzan.com/portfolio-item/liquidi/

📩 Contact us today for a personalized consultation: https://www.dolzan.com/en/contatti/